Dignified Homes in 72 Hours

When disaster strikes, families shouldn't wait months for shelter. Uplift delivers battery-powered microhomes directly to survivors' properties—no utility hookups required.

The Crisis in Disaster Housing

Every year, millions of Americans lose their homes to hurricanes, floods, and wildfires. Current options force survivors into impossible choices: crowd in with relatives, sleep in cars, or wait months for government trailers placed miles from their communities.

The typical FEMA housing unit takes 4 months to deploy, costs $135,000, and requires utility hookups that may not exist for weeks.

“Appalachian people don't leave. Families have been on their land since pre-Revolutionary War times. Solutions must come to them.”

— Field research, Western NC post-Helene

Traditional Disaster Response Timeline

On-Site. Off-Grid. Ready in Hours.

Microhome product render

(3D visualization coming soon)

Everything You Need to Survive

The Uplift Microhome is a complete, self-contained living space designed for rapid deployment. No infrastructure required—just place it on any flat surface and move in.

Technical Specifications

Battery Powered

10kWh integrated battery with optional generator backup. No grid required.

Water Independent

25-gallon reservoir with pump system. Refill from any source.

Forklift Deployable

Fits 4 units per truck. Place with standard equipment—no crane, no foundation crew.

Property Placement

Deploys to survivor's own land. Communities stay intact.

From Stockpile to Shelter

Pre-Positioned

Units manufactured and stockpiled in disaster-prone regions. Ready before storms hit.

Rapid Deployment

When disaster strikes, units loaded 4-per-truck and transported to affected areas within 48 hours.

On-Site Placement

Forklift places unit on survivor's property. Occupant moves in same day. No hookups, no waiting.

Our model: We partner with state and county emergency management agencies who reserve capacity before disasters strike—ensuring units are ready when needed most.

What We've Learned

Insights from disaster survivors, relief workers, and emergency management professionals.

“People won't leave their property. They'd rather sleep in tents at zero degrees than relocate. Fear of condemnation, fear of looters, deep attachment to their land.”

— County Recovery Leader, Western NC

“If you can get people power, you can get them safety. If you can get people power, you can get them communication. If you can get people power, you can get them water.”

— Disaster Relief Nurse, Hurricane Helene Response

“This is a huge piece that's missing from disaster recovery—something off-grid capable, that doesn't rely on utility hookups, that can be mobile based on the breadth of the disaster.”

— Relief Organization Project Manager, North Carolina

“The more convenient it is in terms of returning people to their normal day-to-day life, the more appetite there's going to be.”

— FEMA Emergency Management Specialist

Built by Engineers Who've Scaled the Impossible

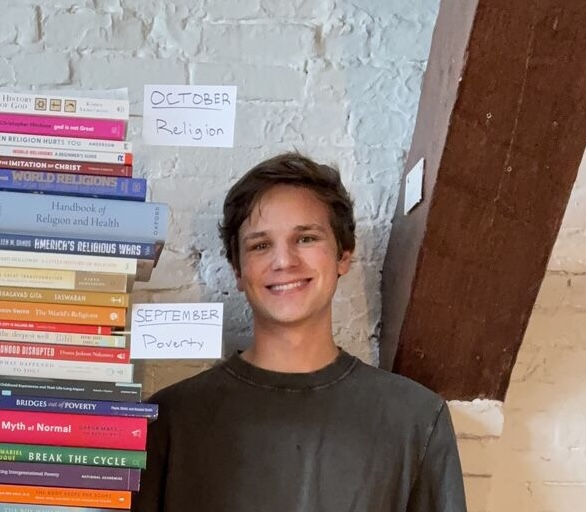

Charlie Nitschelm

Founder

Background

SpaceX Starlink manufacturing (2020-2025). Helped scale production from hundreds to millions of units. MIT LGO candidate.

Superpower

High-volume product design. Making complex things manufacturable.

Trevor O'Leary

Co-Founder

Background

Tesla Senior Software Engineer & Team Lead (2021-2025). Built systems to manufacture vehicle electronics at scale. Harvard MS/MBA Engineering Sciences.

Superpower

Electronics, battery systems, software. Making things work reliably off-grid.

Our backgrounds taught us that the hardest problems—scaling Starlink, building Tesla's battery systems—require relentless iteration and design-for-manufacturing discipline. We're applying those lessons to a problem that matters.

Where We Are

First prototype completed

September 2025

20+ interviews with disaster survivors, FEMA officials, relief workers

Harvard NVC semifinalists

MVP development

Target: September 2026

First pilot deployment

2027

Backed by

Join the Mission

Whether you're an emergency manager exploring solutions, a disaster relief organization, a potential partner, or someone who wants to help—we'd love to hear from you.